power cord manufacturers

Your Single-Source Manufacturer for all of Your Standard and Custom Power Cords Needs.

Power cords and cigarette lighter cords provide power to everything from office computers and manufacturing machinery to automotive devices. At DCpowercord, we are proud to offer a broad range of power supply cords designed to meet today’s varied and specialized electronic applications. Our cords are available in both stock and custom configurations for all common applications and appliances across many industries. Choosing the right cord for you and your company project is key to long-lasting, reliable performance.

Also,We are a professional cord manufacturers, we put a strong emphasis on quality. Our knowledge and expertise is the heart of our quality assurance process and promise of excellence to our customers. Our wide range of certifications stands as a testament to our quality and reputation. Those certifications include: RoHs, SGS, UL, CE, VDE, CSA certificates.We are professional power cord manufacturers.

Power Cord Manufacturers New Products

Main Products

Product Name Product Name

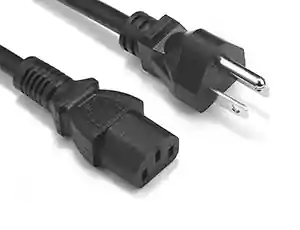

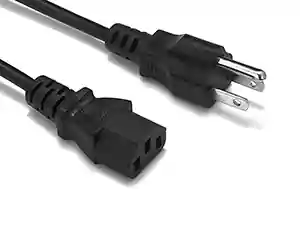

American Power Supply Cable 1.5m 3 Prong NEMA 5-15P US Plug IEC C13 IEC

Product Name

Product Name

Product Name

Product Name

Product Name

Product Name

Product Name

Power Cords Use Case

What Do You Need to Work From Home?

- Computer

- High-Speed Internet

- Noise-Canceling Telephone or

- Headset With a Microphone

- External Webcam

- Printer and Scanner

But you find yourself in a frustrating situation, while you need all the equipment listed above, all that equipment needs power cords! Without it, working from home wouldn’t be an option.

Electric Vehicles

High-quality cables and power cords make optimized performance possible in sustainable automotive products of all types, including:

- Battery electric vehicles

- Hybrid vehicles

- Personal electric vehicles

- Low-speed electric vehicles

- Charging stations

Your Appliance Connection Solution

Appliance power cord flexibility and durability ensure a reliable connection for your next home installation project. This high-quality power supply cord has been thoroughly tested and is backed by a 5-year limited warranty.

- RIGHT ANGLE PLUG HEAD

- 15A/125V/1875W

- 3 STRIPPED & TINNED WIRES

- UL LISTED

- 5-YEAR LIMITED WARRANTY

Ideal Solution For Network Devices

The C13 C14 extension power cord is an ideal solution for connecting your PC or peripheral device containing a C14 input. Featuring an IEC320 C14 connector on one end and an IEC C13 connector on the other, it extends the power connection of most network devices using a removable power cord. It also can directly connect components into a compatible UPS, PDU, surge protector, or AC outlet.

GET A FREE QUOTE FOR YOUR PROJECT

Our team is ready to support your next project, so contact us today!

What is Power Cords?

Are you looking for a power cord manufacturers that can design, engineer, and power cord manufacturers to your companies specifications? Why not choose DCpowercord? DCpowercord is a power cord manufacturers and supplier. Since 2012, we have been helping businesses create, innovate, and excel within their industries by manufacturing top-quality power cords and providing extensive value-added services.

To help you understand the power cord, we have prepared a technical article on the power cables; through this article, you can learn the following knowledge:

What is Power Cords Called?

A power cord or mains cable is an electric cable that temporarily connects a home appliance to the mains power supply through an electrical outlet or extension cord. The power line can be used to transfer direct electrical current (DC) or alternating electrical (AC). Many cords are AC power cords that the direction energy in which the instructions of current flow are periodically reversed. The AC power supply cord consists of a wire made up of highly conductive material such as bare copper, bordered by an insulative material, then sealed in a protective outer jacket with a plug cover to ensure safety and security around the electric outlet.

What is the difference between a power cord and an extension cord?

Cord & Cable sets are made use of in any application that requires the existence of electric energy to operate, such as workplace, factory automation industry, medical machinery, the lighting industry, etc. For specialized equipment such as TV, computers, monitors, audio, lighting equipment, and electric power tools, made use of in locations without a convenient power source, extension cords can carry the electric current up to hundreds of feet away from an electrical outlet.

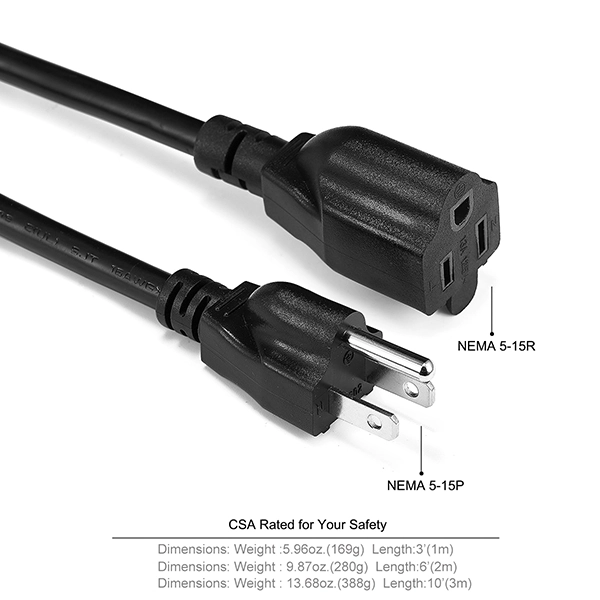

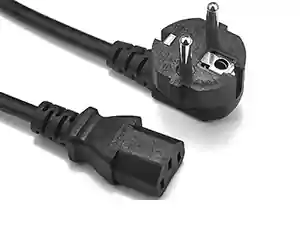

What is the difference between the NEMA power cord and international power cords?

In North America, NEMA power cords are the standard for electric plugs, cable voltage capacities, and also receptacle configuration. International power cords, plug adapters are used in conjunction with electric appliances in countries different from those in which they were designed to operate.

Power Cord Features

Retailers, hospitals, almost all manufacturers, and every organization in our commercial globe use power cables every day. Electrical power cords are the path on which power travels from a power supply to the equipment. Experts rate power using volts (or kilovolts, kV, for larger quantities), so the potential of a specific cord is established by how much power it can deliver. When selecting the ideal power cable type to be made use of for various applications, there are many variables to be considered, such as equipment area, period of use, the stress of the operation, etc. Power cable manufacturers abide by standard policies for voltage scores, current, wire size and also length, coat material, optimum wire temperature level, as well as the kind of shaped electric plug and also female receptacle to be made use of. The ability of a cord to successfully take care of the needed flow of electrical power will certainly depend upon these elements, and the high quality of electrical power transferred will undoubtedly be influenced as necessary.

Electrical cable sizes and voltage abilities are assigned according to the American Cable Scale (AWG) standards. The ideal wire dimension is therefore identified by the amount of voltage needed to move via the cord. The cord shape can be either flat or round according to whichever is more appropriate for the application. The coating material is an additional consideration and may be determined by the intended use and the place of the power cable. For example, suppose the cord is purposed for rough, outside usage. In that case, a coating material will undoubtedly be water-resistant and a lot more sturdy than a cord planned only for use indoors, for instance, with a laptop. An additional factor to consider for jackets is the feasible presence of electromagnetic interference and whether the wires in an AC power cable need further protection, such as those used with medical tools.

The National Electrical Manufacturers Organization (NEMA) is in charge of setting the stringent standards utilized in The United States and Canada for electrical supply components. This ensures top quality of electric supply is preserved. Other countries have their voltage systems and electric component formats; therefore, those corresponding countries figure out the standards and controls implemented in their power extension cords.

Production standards such as those applied by NEMA assist in keeping consistency in power cable manufacturing and reducing the possibility of malfunctions due to top quality criteria. Similar to any part utilized in the transferring of electrical power, there are essential safety preventative measures to be embarked on in making use of power cords. Injury, fatality, and/or extensive residential property damage can occur as the result of damage, malfunction, or abuse of electric devices. Also, it is essential for there to be procedures in place to decrease these dangers. Polarization, or grounding, is a necessary aspect of electrical plugs and appliances, especially for more great voltage appliances or for electric devices that have a higher threat of triggering electric shock when in real-time. Delicate electric tools and also products need just to be used with polarized or grounded cable sets. Other safety and security precautions for electrical supply parts include plug covers, water-resistant protective materials, merges, and breakers.

Power Cord Connectors

IEC 60320 power cables have been available in regular and high-temperature variations, along with numerous rated currents. The power cord connectors have a little different shape to ensure that it is not possible to replace a cord with a lower temperature level or current ranking, but that it is feasible to use an overrated line. Cables additionally have various sorts of outdoor jackets available to fit environmental variables such as moisture, temperature level, oils, sunlight, versatility, and hefty wear. For example, a home heating appliance may come with a cable developed to withstand accidental contact with heated surface areas.

Worldwide, more than a lot of various kinds of AC power electrical plugs and sockets are used for dealing with building electrical wiring. Products sold in many different markets can use standard IEC 60320 connectors and afterward utilize a removable power cable to match the local electric outlets. This simplifies security authorizations, factory screening, and manufacturing, considering that the power cable is a low-priced item offered as a product. Since the same sorts of appliance-side ports are utilized with both 120 V and 230 V power lines, the individual has to guarantee the linked devices will run with the offered voltage. Some widgets have a slide switch to adapt to various voltages or extensive power products.

History of the power cord

Thomas Edison created the very first power circulation system in 1882. He made use of a three-layer cord that included a copper rod covered in a veggie fiber (called jute) to develop a package cord. Those two layers were, after that, wrapped in a bituminous layer for protection.

Copper was used because it is a remarkable conductor of electrical energy. The various other layers held the copper with each other, protected it, and gave people a level of protection from the harmful impacts of electrical power.

Vulcanized rubber soon changed the bituminous layer. It is an efficient insulator, which implies it is not a reliable conductor and can stand up to greater temperature levels than the bituminous layer.

The development of technology as well as new products was established much better matched for electrical functions. PVC, or Polyvinyl chloride, is currently commonly utilized for electrical cables. PVC is a plastic that can stand up to higher temperatures, which makes PVC power cables effective and risk-free.

How are power cables made?

power cord manufacturers can be broken down into two parts:

A conductor is a material through which electricity can flow. Electrical conductors are made up of metals such as copper, aluminum, etc. These metals are used to make wires. Most wires are made out of copper because it conducts electricity with high flexibility and very little resistance.

The first stage in the manufacturing process of a conductor is wire-drawing. The wire-drawing was gradually reducing the wire’s diameter to fit its final diameter to increase ductility and conductivity.

Once the diameter is reduced, the wire is drawn further to decrease the diameter of the wire to the size needed for each kind of conductor.

In the second stage of this process, the wires undergo a heat treatment called annealing. Annealing is a process of heating metal and allowing it to cool slowly to remove internal stresses and toughen the metal. The point of this treatment is to increase the conductivity of the wire.

Now we need insulation. Insulators are different synthetic materials that are used to insulate electrical wires. Because the current runs along the outside of the copper wires, they need to be insulated from other wires and conductive surfaces. An insulating cover over the conductor also prevents any current leakages. Different insulation materials may be used depending on the characteristics of the cable required. The quality of an insulation material depends on two basic characteristics: insulation capacity and heat resistance.

Cables sometimes contain several different wires wrapped together in an insulator. In some cases, the cable may require additional elements to improve protection. For instance, electrical coverings called “screens” insulate the signals circulating in the cable, shielding the power cables to prevent them from external interference.

And THAT is how an electrical conductor is made once the diameter is reduced, the wire is drawn further to decrease the diameter of the wire to the size needed for each kind of conductor.

In the second stage of this process, the wires undergo a heat treatment called annealing. Annealing is a process of heating metal and allowing it to cool slowly to remove internal stresses and toughen the metal. The point of this treatment is to increase the conductivity of the wire.

Now we need insulation. Insulators are different synthetic materials that are used to insulate electrical wires. Because the current runs along the outside of the copper wires, they need to be protected from other cables and conductive surfaces. An insulating cover over the conductor also prevents any current leakages.

Different insulation materials may be used depending on the characteristics of the cable required. The quality of an insulation material depends on two essential features: insulation capacity and heat resistance.

Cables sometimes contain several different wires wrapped together in an insulator. In some cases, the line may require additional elements to improve protection. For instance, electrical coverings called “screens” insulate the signals circulating in the cable, shielding the power cables to prevent them from external interference.

And that is how an electrical conductor is made!

Are universal power cords safe?

The AWG (American wire gauge) Universal Power Cord contains features that come by design. Some of these features are the cable design which allows maximum durability and long life for the electrical cable through any device used. It provides the power that is needed and sufficient enough for the device and keeps the power cable at a safe status.

The AWG Universal Power Cable can also be used as a power extension cord easily without any problems. All you have to do is plug into an electric socket and extend by fitting the cables together. It makes a perfectly safe extension cord and is long enough to be sufficient for no use of other extension cords.

This article includes power cord history, differences, features, and IEC connectors. If you have other questions and suggestions about power cords, please feel free to contact us, and if you and your company need custom power cords for your project, why not contact us? We will provide design solutions based on your project.We are professional cord manufacturers.